便宜的灌装包装罐蜂蜜灌装机

1、全自动蜂蜜灌装机

NP-VF全自动蜂蜜灌装机是专为将粘性蜂蜜灌装到玻璃罐和宠物瓶中而设计的,也称为蜂蜜灌装机、蜂蜜罐包装机。是蜜蜂工厂的理想选择。

2. Different types of VKPAK automatic honey filling machine

蜂蜜灌装机根据容量的不同有多种型号和类型,灌装喷嘴数量从1头到16头,灌装量从 5g到20g,100g到1000g,甚至1000g到5KG。

三、蜂蜜填料的主要结构

-20L 至 200L 顶部料斗可选,双夹套料斗 加热混合系统 作为选择,

-机器主体由304SS制成

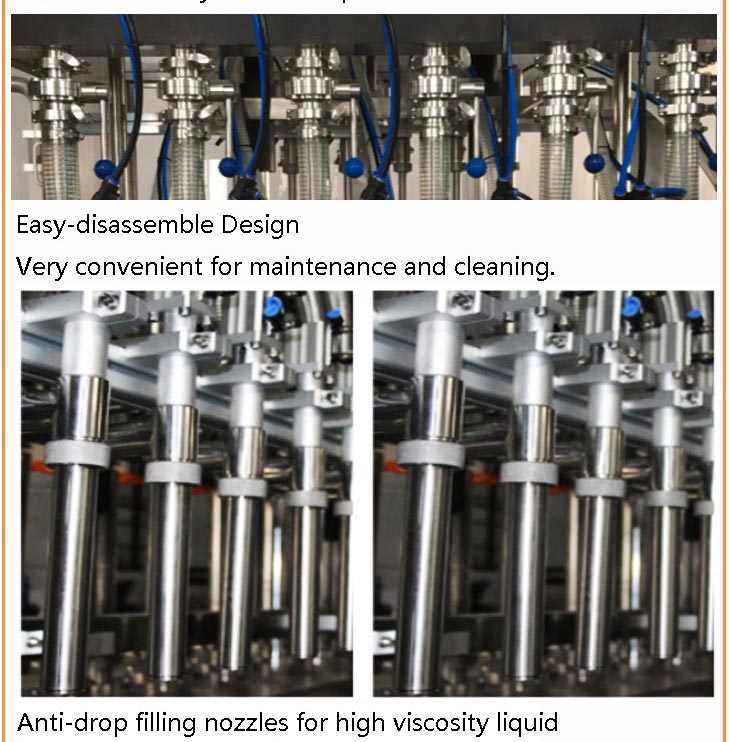

-灌装嘴,灌装嘴是专门为 关闭和丝绸切割蜂蜜

-灌装嘴由气缸上下移动,伺服电机上下移动可选

-PLC控制系统,HMI操作

-特制的马和蜂蜜阀门, 与CIP系统连接马。

4、全自动蜂蜜灌装机的竞争优势

自动挡有很多优点 蜂蜜灌装机

-PLC控制,触摸屏操作。

-松下伺服电机驱动,在人机界面上自动调整灌装尺寸,例如。用户想要填充500g蜂蜜,

用户只需输入数字500,机器就会自动调整

- 活塞容积式,灌装精度高

-带顶 双夹套加热和混合罐,防止蜂蜜结晶 停工一天或多天后。活塞和软管也可以加热。

- 全自动蜂蜜灌装机还可以通过CIP系统连接用户CIP系统的功能

-蜂蜜填料的马是根据蜂蜜性质特制的,无死角,食品级

- 蜂蜜灌装机上的软管或管道采用世界品牌 东洋 来自日本

- 专为粘性蜂蜜输送而制造的旋转阀

5. 主要技术

| 灌装喷嘴 | 1-16个喷嘴 |

| 生产能力 | 每小时800 -5000瓶 |

| 灌装量 | 100-500ml,100ml tp 1000ml |

| 功率 | 2000W,220VAC |

| 准确性 | ±0.1% |

| 驱动的 | 松下伺服电机 |

| 面 | 施耐德触摸屏 |

6. 全自动蜂蜜灌装机主要特点

a) 要填充的产品:

1)热灌装(35~40℃),冷灌装常温

2) 比重:1.1 ~1.4 gr/cm3

3) 涂抹巧克力 • 蜂蜜 • 涂抹奶酪酱、糖蜜。

b) 瓶型:

1) PET 瓶 • 象限横截面 • 体积 250 毫升。 • 颈部 32 毫米。

2) 玻璃罐和 PE、PET 罐 • 圆柱形横截面 • 体积 200 ~ 350 毫升。

3) 颈部 45 毫米。

c) 填充公差:+/- 最大 0.5%

蜂蜜灌装机基本组成

1.1 瓶子和罐子的空气清洁。

1.2 自动进瓶和支架(如果需要塑料瓶)

1.3 不滴水。

1.4 输出 20 ~ 100 bpm。

1.5 无瓶无填充

1.3 带PLC触摸屏的控制面板。麦芽灌装程序保存。

1.4 双夹套料斗:

• 180 升容积, • 液位检测器。 • 电加热器。

• 产品的温度检测器和控制 • 搅拌器

1.5 灌装系统和喷嘴易于拆卸清洗。

1.6 机身为SS 304,与产品接触的所有部件均为SSL 316。

我们的机器 VS 其他供应商

| 项目 | 我们的机器 | 其他供应商 |

| 顶罐 | 双夹套电加热罐 | 不 |

| 活塞 | 带热水循环加热系统 | 不 |

| 连接管子和软管 | 带热水循环加热系统 | 不 |

| 灌装喷嘴 | 关闭和反丝填充喷嘴 | 不 |

| CIP系统 | 我们的机器可以连接CIP系统 | 不 |

我们的服务

安装与调试

-如果有要求,我们将派工程师在买方的位置进行设备的安装和调试。

-国际双向机票,住宿,食品和交通,医疗的费用应由买方为工程师支付。

-正常的调试期限为3-7天,买方应为每位工程师每天支付80美元。

-- 如果客户没有上述要求,则客户需要在我厂进行培训。安装前,客户需要先阅读操作手册。同时,w

e 将向客户提供操作视频。

训练

-我们提供机器培训系统;客户可以在我们的工厂或客户车间中选择培训。正常的训练天数是1-2天。

保证

-售出的机器将在一年内提供保修。

-在保修年度内,由于供应商的质量问题而损坏的任何备件将免费为客户提供,如果包裹重量超过500克,客户需要支付运费。

-易磨损的备件不在保修条款之内,例如O形圈,皮带将随机器一起提供一年使用。